Borescope inspection leads to efficiency gains and improved research results

Engineers at IAAPS are using specialist borescope equipment by Olympus to undertake visual inspections of Internal Combustion Engines (ICEs) and other powertrain sub-systems as part of the research and testing projects conducted at the institute. Below, Dr Andrew Lewis, IAAPS Principal Engineer, Dr Karl Giles, IAAPS Senior Engineer, and Bayard Morales, Product Marketing Manager at Olympus, discuss the key benefits and importance of the borescope application in automotive engine R&D.

What is the nature of the partnership between IAAPS and Olympus?

Andrew Lewis: It initially started as a regular supplier / customer relationship. We had another version of this type of visual equipment from a different company, which was a lot more basic and was giving us very poor images. One of our automotive clients recommended Olympus, and we have been using their borescope since November 2020. We have been working closely with Bayard and the team at Olympus to learn the proper application of the system and how to get the best results out of this type of inspection for the research and testing that we conduct. From Olympus’ perspective, it is useful to see how a research facility like IAAPS is using their borescope in small, confined spaces such as the combustion chambers of passenger car engines, and it has been a very fruitful partnership so far.

How exactly is borescope inspection utilised within IAAPS and its research projects?

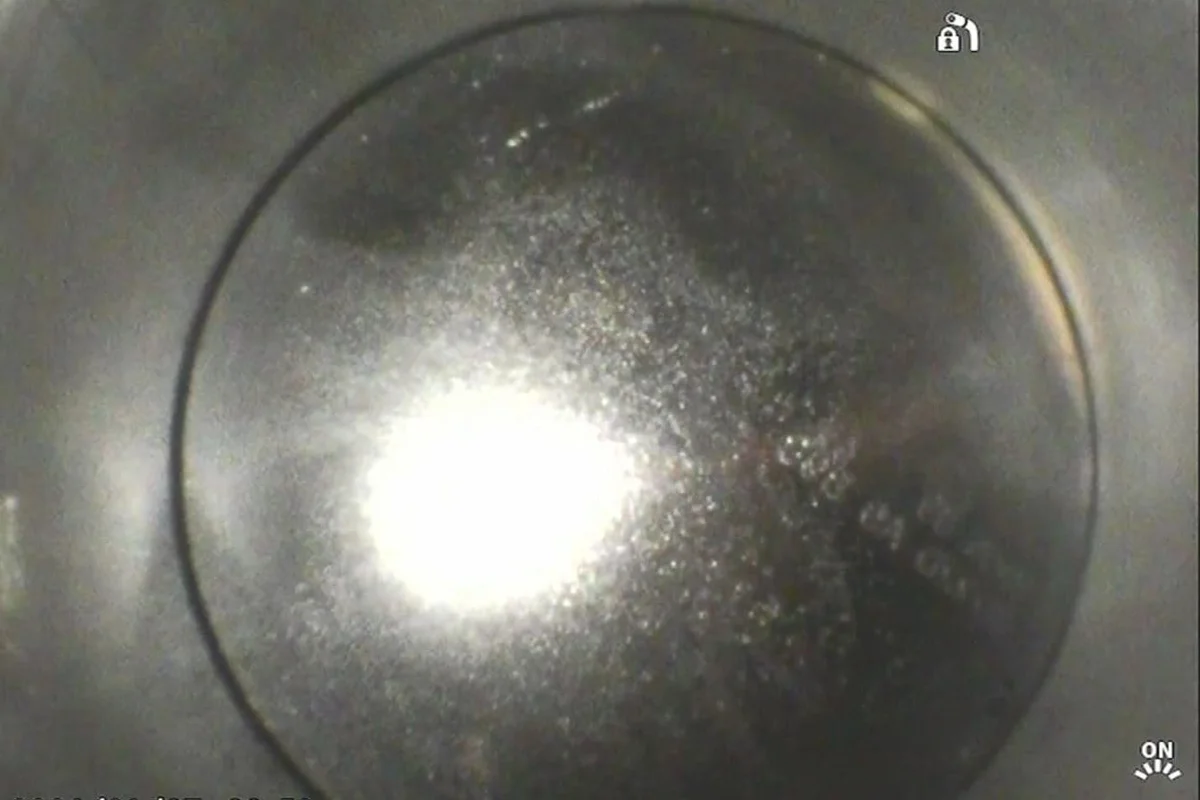

Andrew Lewis: A borescope is a remote optical device, designed to assist the visual inspection of tight, difficult-to-reach cavities. It consists of a narrow, flexible probe with an articulating head at one end that houses the lens and image sensor, and a remote control for controlling the position of the articulating head at the other. It is a very capable piece of equipment, and the user has the option to fit a range of forward or side-facing lenses, depending on the requirements of the inspection being carried out. Our device is 4mm in diameter, so we can get into the really hard to reach places within an engine. The nature of our work means that we are often pushing the boundaries of what the engine can do, so it’s not uncommon for things to break or wear faster than normal. The Olympus borescope allows us to observe what is going on inside an engine and detect any damage or wear before a catastrophic failure occurs.

Karl Giles: We predominantly use it for routine inspection of internal combustion engines. Using a borescope for this purpose is pretty standard practice, however it’s rare for engines outside of power generation and aviation to be inspected this way. The engines we work on are tiny in comparison to those used in power generation, which makes it much harder to get the shots you’re after because you’re working in much more confided spaces. Besides petrol and diesel combustion chambers, we’ve also used the borescope to inspect turbochargers, diesel after-treatment systems, the sump and heating elements of our new single cylinder rig. Basically, anywhere that’s hard to reach without significant disassembly!

What are the benefits of the equipment?

Karl Giles: We have learned a lot from using it. For instance, the results of our inspections have led us to take mitigating action to correct certain undesirable effects or prevent them from getting worse, or to guide the types of testing that we subsequently carry out. Essentially, it helps us identify issues early and take corrective action before anything breaks. The image quality is great and we’ve never found we needed a higher resolution. The accessory set is pretty comprehensive, too, even though we actually get by with minimum accessories.

Andrew Lewis: The borescope inspection adds a significant visual aspect to our research and can help answer why data from test results may be looking differently or certain phenomena may be happening that we did not anticipate – there is always a trail of evidence which helps us to better understand our findings. Without it, we can only look at the numbers coming off our sensors for temperatures and pressures and so on, but being able to use the borescope gives us a visual indication and helps us to interpret the results.

Furthermore, we are making significant efficiency gains and cost savings by using this type of internal inspection. Take the typical use-case of looking inside the combustion chamber itself. In order to do that without the borescope, you would have to physically strip off the front end of the engine, take all of the systems apart, take the cylinder head off etc. The quickest we could do that – with specialist tools – and then rebuild the engine is two days, which is two days of downtime on that engine. However, this allows us to look in and be done within an hour. It’s a huge time saving versus losing two days and potentially not even seeing any results.

What does this partnership mean for Olympus?

Bayard Morales: For us the most interesting part is to see how the borescope equipment for engine inspection is used in a research environment such as IAAPS; we can learn what works in its application and what doesn’t and make changes accordingly. Ultimately, the idea behind the borescope is very simple: to see a part of the machinery without having to disassemble it, but it adds a lot of value to the research process.

Olympus are by no means the only providers of this type of equipment, but I would consider ourselves market leaders and we strive to improve and work closely with our clients so they get the most out of our equipment. We focus on image quality, because, at the end of the day, our customers need to be able to get high-resolution visuals to be able to see inside and make decisions based on their findings. So, having this relationship with the engineers at IAAPS and their feedback is extremely valuable to us.

The collaboration between IAAPS and Olympus is resulting in a best practice guide. Can you give more details?

Bayard Morales: I realised that when we supplied IAAPS with the kit, there was no extensive guide on how to use the borescope for this particular application. As IAAPS has the knowledge on engines and we have the know-how on the borescopes, we thought it might be a good idea to start working on a best practice guide. I spent an afternoon onsite at IAAPS with the engineers to see exactly how they are using it, and from that I took videos and notes which will form the basis for a short manual. My initial aim was to train my own colleagues, but it turns out that it will be just as useful for IAAPS to have as it will mean that any new members of staff will be able to quickly get to grips with the equipment, so we can share it between our organisations.

Karl Giles: We currently don’t have any formal instructions in place, and information is passed down via demonstrations, so it will be great to have a guide document or resource that we can point to when we train our colleagues. So far, we have had very positive feedback from our clients on the results of the inspection and the clarity of our photos, which is obviously a credit to Olympus and their equipment but also to Bayard and the support that he has provided us. I’m sure the best practice guide will further cement this and that we can continue to build on our capabilities.

Andy Lewis: Let’s be honest, it is a considerable investment to have one of these borescopes, so you definitely don’t want to use it incorrectly because it could cost a lot to fix it. There are a lot of factors to consider to ensure safe operation of the borescope (engine temperature for instance) so having all of those in one place would be very beneficial.

Title

Lorem ipsum dolor sit amet, consectetur adipiscing elit

As we move towards electrification, will borescope inspections still remain relevant?

Karl Giles: Yes, I believe so. Downstream powertrain components such as gearboxes and transmissions are going to look quite similar regardless of whether they are being driven by an electric motor or an internal combustion. In an R+D environment like ours, there will always be a benefit to being able to inspect these sub-systems without taking them apart. We haven’t had a huge amount of experience using the borescope in this capacity, but I would expect demand to grow as we see an increase in project work on electrified powertrain systems at the new IAAPS facility.

Andy Lewis: Yes, transmissions are always going to be around. Even if internal combustion engines die a death, gearboxes and transmissions will still have to work with electric machines, so there will be a requirement for internal inspections. In relation to electric machines, borescope inspection may take the form of physically looking inside a motor to inspect the windings for signs of thermal damage for example. As electric motors become increasingly powerful, there is going to be more complicated thermal management around them with integrated cooling galleries etc. Inspection could therefore involve checking for any residue of coolant leaks or oil leaks within the motor. There is always going to be a need to see inside of a piece of equipment without disturbing it because that way you can be confident that what you are seeing is not a result of the disassembly process. The more questions you can answer without disrupting the whole system, the better. Nowadays, everyone is looking for efficiencies, and the cost of running a powertrain facility is very high. If you’re losing a day to disassemble and reassemble, that’s a huge expense, and if you’re doing that every week because you’re breaking and inspecting components, that all adds up. If you can minimise that inspection time to half an hour because you can put a camera in there, well, borescopes will pay for themselves within a couple of weeks’ worth of testing.