The forefront of propulsion R&I

Automotive

Who we work with

Our network of collaborators ranges from Original Equipment Manufacturers (OEMs) through Tier 1 Suppliers to SMEs and over 134 research projects to date, as well as being aligned with the Advanced Propulsion Centre (APC).

Supporting the rapid transition to low carbon mobility

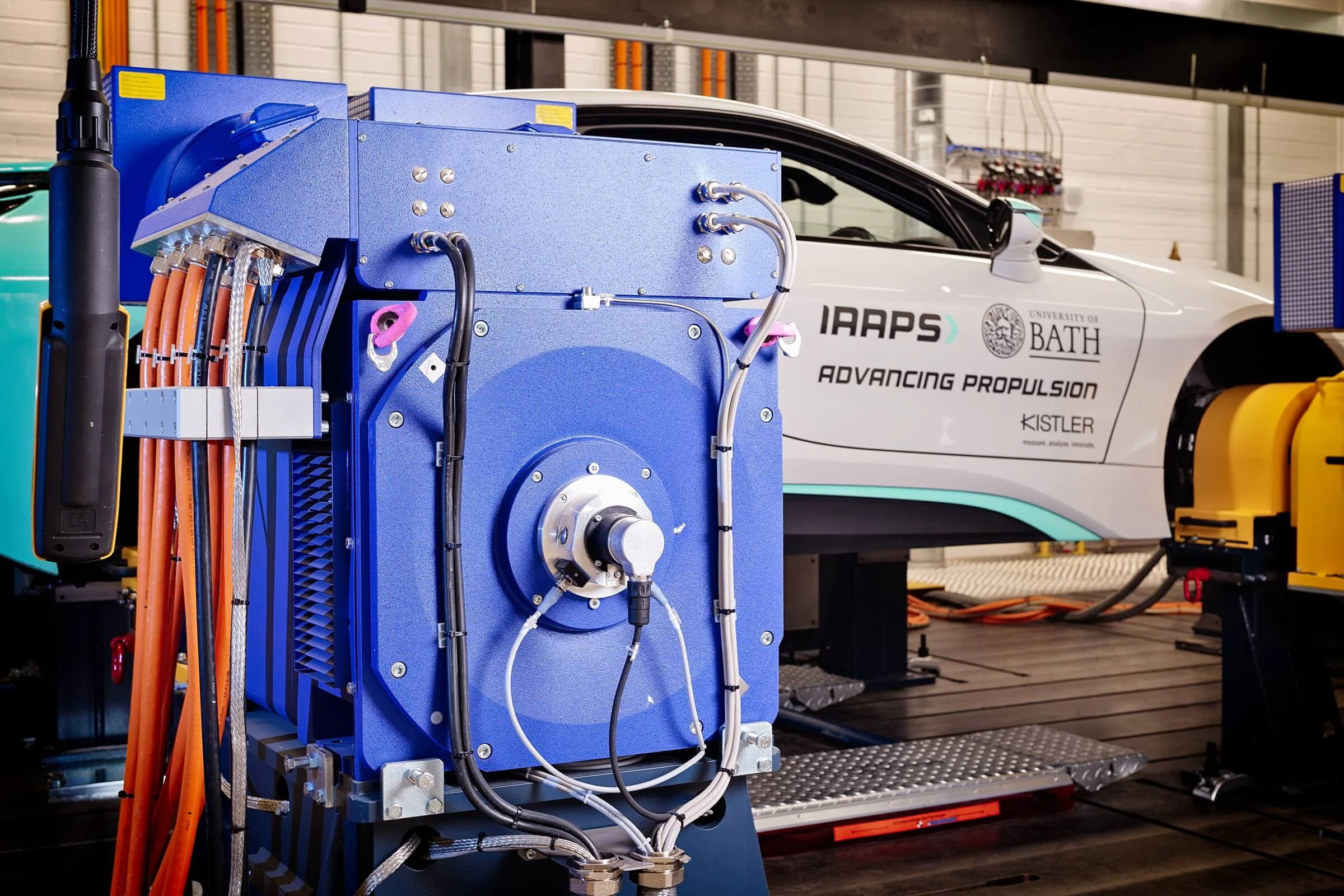

Rooted in more than 40 years of propulsion systems research at the University of Bath, we operate at the forefront of engineering innovation, with long-standing relationships with key automotive stakeholders, strong industry links and close ties to policymakers and legislators.

Cross-disciplinary and bespoke R&I

Our work covers the breadth of automotive propulsion technology, with world-renowned, specialist teams providing cross-disciplinary and integrated R&I, bespoke to the needs of our partners. Our new IAAPS facility is a world-class, state-of-the art innovation hub with cutting edge test and development equipment and capabilities that are deployed to meet the most demanding system characterisation and design validation needs of our customers, covering the full range of propulsion technologies.

How we did it

We work closely with our partners and build lasting, profitable and productive relationships. Find out about our success stories and the impact we have made below.

Looking to collaborate on a project?

We are a collaborator of choice for sustainable partnerships underpinned by first-class infrastructure and one of the world's most highly respected and experienced propulsion research and engineering teams.